服務項目|SERVICE ITEMS

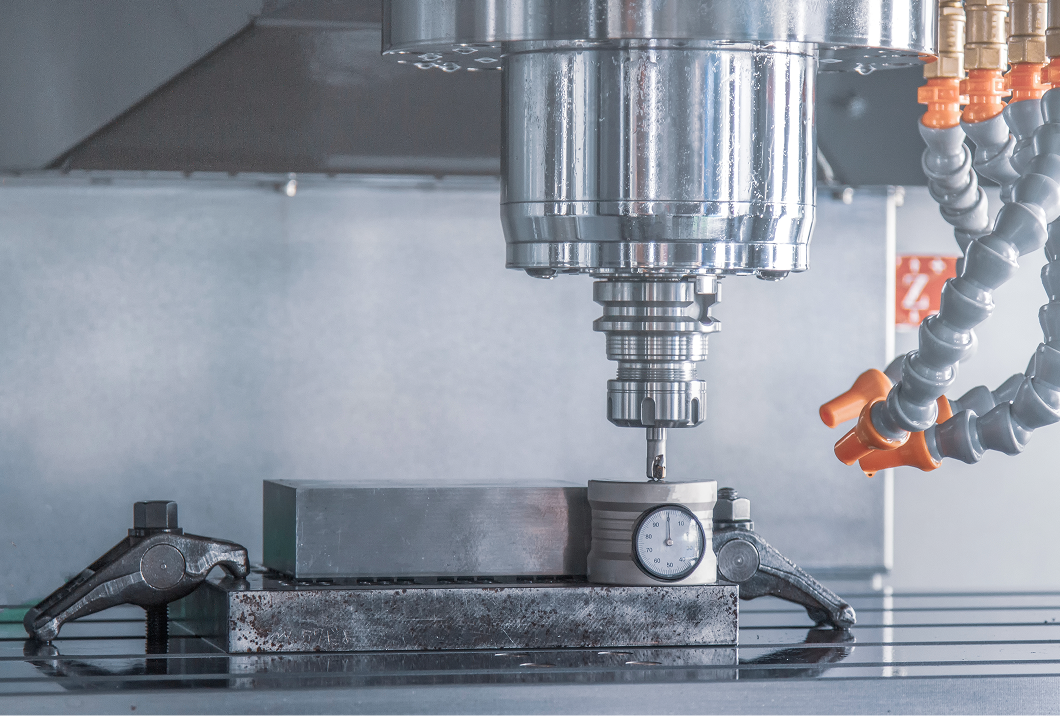

We provide one-stop manufacturing services integrating CNC machining, fixture design, prototyping, and mass production.

Focused on High-Precision Manufacturing and Integrated Services

Sky Bold Engineering Industrial Co., LTD brings years of experience in precision machining and mechanical development, delivering a complete, stable, and traceable manufacturing process—from R&D prototyping and fixture design to mass production.

We tailor machining technologies and quality control to each product’s requirements, improving reliability and accelerating development and production.

01

High-precision milling suitable for aluminum, steel, stainless steel, and complex-shaped components. Supports both low-volume, high-mix production and stable mass production.

02

Equipped with turn-mill capabilities, we can process shaft components, threaded features, and cylindrical structures. Delivering stable dimensional accuracy, our solutions are well suited for high-repeatability requirements.

03

Custom-designed jigs and fixtures tailored to specific equipment or production line requirements, enhancing assembly and inspection efficiency.

04

We support the design and optimization of custom mechanisms, validation parts, and modules, helping to shorten R&D and verification timelines.

05

Ideal for low-volume prototyping, part modifications, and design testing during the R&D phase, with flexible support and fast turnaround times.

06

Equipped with professional measuring instruments, we provide dimensional reports, measurement records, and full traceability control.

07

We integrate processes such as anodizing, sandblasting, electroplating, grinding, and coating to provide one-stop post-processing services.

08

Supports the machining of large platforms and base components made from tool steel, stainless steel, and aluminum.

09

We assist with component assembly, calibration, and functional inspection.